by ValleySounds Mon Nov 11, 2013 4:53 pm

by ValleySounds Mon Nov 11, 2013 4:53 pm

sKiZo wrote:Jeez ... I go away to make some popcorn and you go and finish the amp!

Looks like one major difference between you and me is, you actually had a plan when you started. Not to mention I cheated by having Panel Express do the hard work on the chassis ... I started out on the drill press here and decided early on that was beyond my capabilities. I also went kit and let Bob do most of the shopping for me. Well, that and your blazing speed ... total time start to finish?

Beautiful build. Certainly a work of art and something to be proud of ...

PS ... glad to see I was of some help in your build. Those meters gave me fits, but it all worked out in the end and they've come in right handy for monitoring the amp. Not fair though ... I had several points where I'd soldered myself into a corner ... you had to have at least one?

I'd hate to have all this popcorn go to waste ...

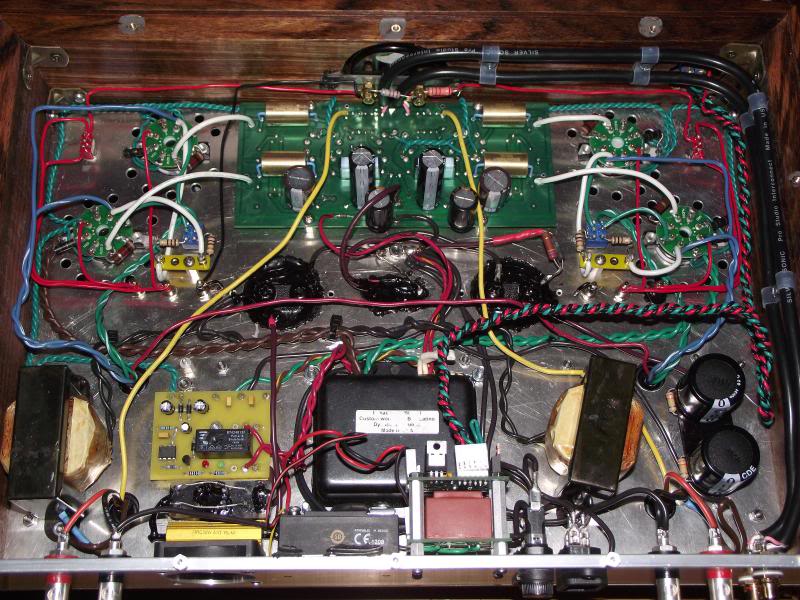

I thought about using panel express but I had no idea what the layout was going to be like until I had the kit in hand. I did use their software to start the design but every hole I added was $$. Lots of parts had to be assembled and moved around the chassis to find the proper mounting position. Then mark holes, disassemble, and drill in proper place. From the whole amp I only had 1 hole not work out as planned (the angled choke should have been straight but the tranny cover mount plate covered it and it couldn't be used). I designed the top cover on the computer, printed a template and started making holes (thought my auto center punch was going to wear out)

Total time of build was right around 2 weeks of working on it in the evenings. There was a few breaks in between while I waited for parts to arrive.

There was a bit of troubleshooting right from the beginning but I think thats what DIY is about.

The mv meter just sat unused in the amp while I read and read and read about how to make it work. Was a way easier to do then I thought.

My voltage at home is sitting right at 122 volts all the time. It took a bit to get the amp into spec where I didnt have to run it from a variac. Thats the 40 Ohm resistor right after the diodes. I got 524 dc on the first cap, 518 dc on second feeding the output transformers and 385 dc on the third feeding the driver board. Without the current draw of the power tubes its right around 585 dc on the first cap

Heat is take care of from the fan on the resistor and diodes. Doesnt even get warm. Power tranny still gets hot but im going to put a fan on the back of the cover.

I pulled a bit of hair getting a bias issue fixed. A big puff of smoke from a resistor. A lot of part swapping to get it voiced to my liking(still in progress

but I like the russian pios so far)

This amp just loves the new kt-120's and it drives my DIY 91db speaks to wall shakin levels.

It sounds much nicer then my very very modified Jolida 801.

Next may be one of Roy's preamps made to match the amp.

Last edited by ValleySounds on Wed Dec 18, 2013 6:11 pm; edited 1 time in total

Heat is take care of from the fan on the resistor and diodes. Doesnt even get warm. Power tranny still gets hot but im going to put a fan on the back of the cover.

Heat is take care of from the fan on the resistor and diodes. Doesnt even get warm. Power tranny still gets hot but im going to put a fan on the back of the cover.