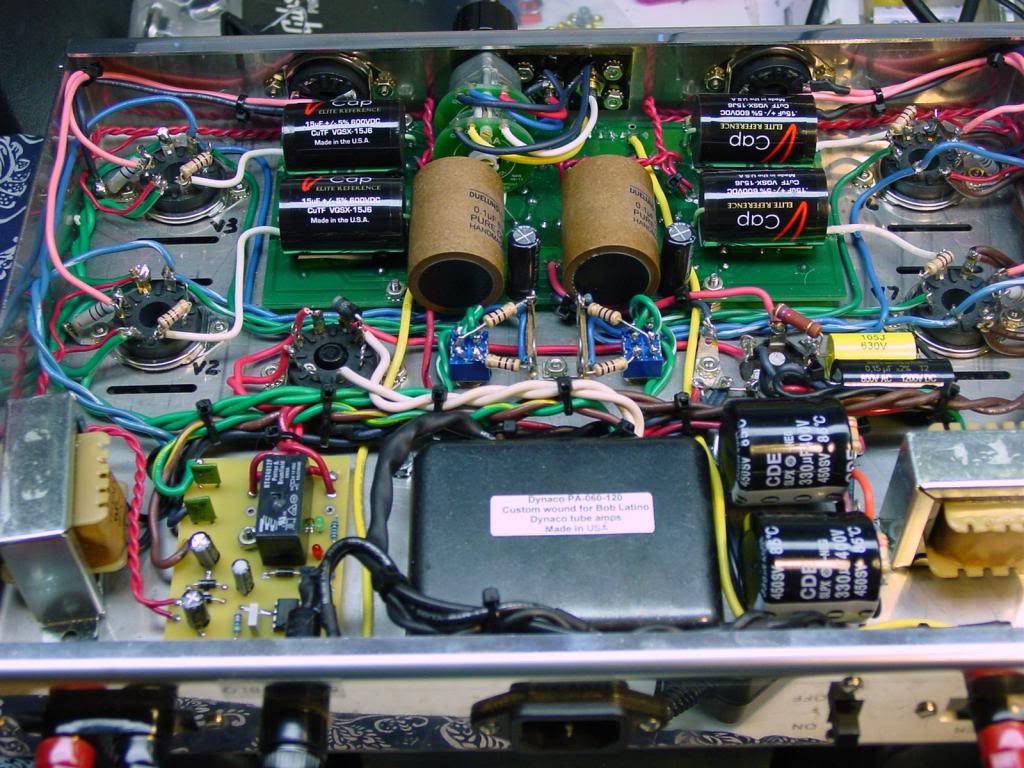

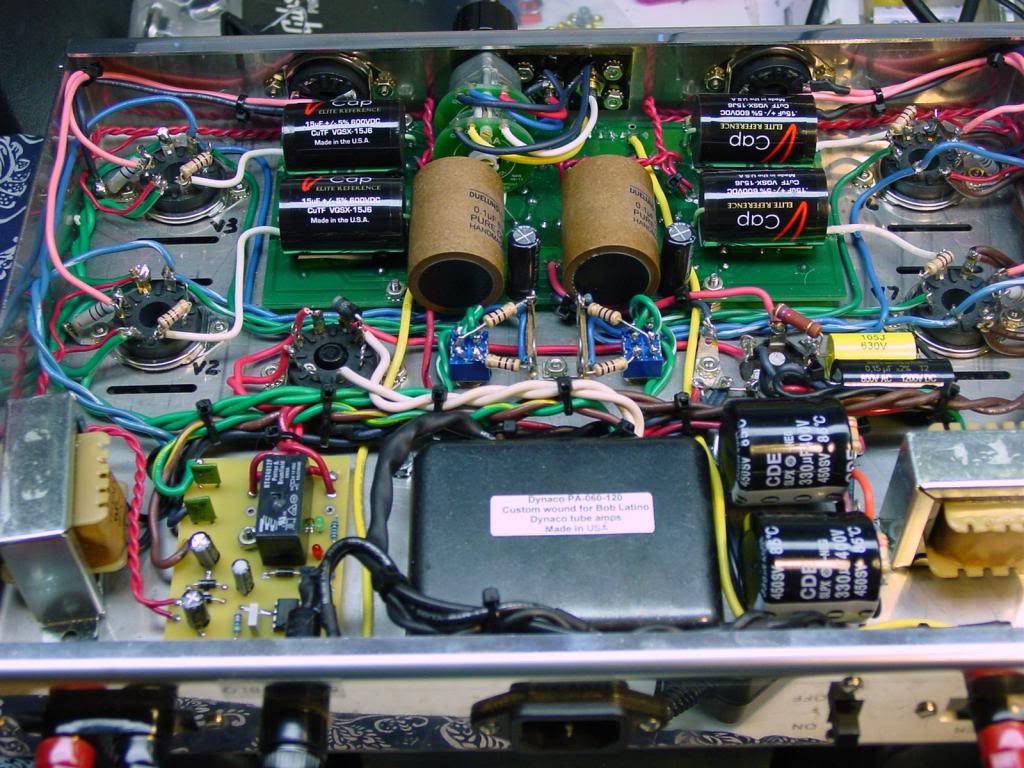

Finished ST-120 wiring yesterday. This is a great kit and enjoyed building it. The chassis is something special. I added an IEC connector and it took two saw blades and a couple of drill bits to get it done. This is one tough chassis.

The ST-120 sounds great. There is no comparison to the AV receiver I have been using even with only a few hours of run in. Good sense of rhythm and pace, reduced harshness, and extremely low background noise. All is good!

I also made a few layout changes to the triode/ ultralinear switches to save wire. I wanted twisted pairs of the plate and screen wires off the switches/ terminal blocks to match the ouput transformer colors. So I saved the green and blue striped wire cuttings from the transformers to route back to the V2 and V7. They were just barely long enough to make the run. The regular green and blue wire transformer cuttings weren't long enough but I had a few spare feet of those colors. This change sure made verification of wiring very simple.

There are also some other wire color changes that attempted to match the pictoral drawing where possible. Also used some shielded cable off the stepped attentuator. And a special nod to Tech Spray solder flux remover. It does the job well but you have to spend some time with cotton swaps to remove the last trace. But it gets it all and leaves you with a clean, professional looking board.

I appreciate Bob's attention to detail and his help. This is a great kit and parts are top notch. Regards, Scott

Edit: Latest mods Caps, Attenuator

The ST-120 sounds great. There is no comparison to the AV receiver I have been using even with only a few hours of run in. Good sense of rhythm and pace, reduced harshness, and extremely low background noise. All is good!

I also made a few layout changes to the triode/ ultralinear switches to save wire. I wanted twisted pairs of the plate and screen wires off the switches/ terminal blocks to match the ouput transformer colors. So I saved the green and blue striped wire cuttings from the transformers to route back to the V2 and V7. They were just barely long enough to make the run. The regular green and blue wire transformer cuttings weren't long enough but I had a few spare feet of those colors. This change sure made verification of wiring very simple.

There are also some other wire color changes that attempted to match the pictoral drawing where possible. Also used some shielded cable off the stepped attentuator. And a special nod to Tech Spray solder flux remover. It does the job well but you have to spend some time with cotton swaps to remove the last trace. But it gets it all and leaves you with a clean, professional looking board.

I appreciate Bob's attention to detail and his help. This is a great kit and parts are top notch. Regards, Scott

Edit: Latest mods Caps, Attenuator

Last edited by arledgsc on Sun Sep 01, 2013 11:31 am; edited 1 time in total