by heyraz Sat May 12, 2012 9:42 pm

by heyraz Sat May 12, 2012 9:42 pm

Harpy,

Very nice work. I rebuilt a vintage ST70 using a VTA driver board last winter totally enjoying the experience as I can tell you are. Using the two Morgan Jones books as reference it was liking taking a course about amplifiers with lab.

I love the way my ST70 sounds and have been considering another project, possibly a pair of MKIII's. I have a couple of questions for you if you don't mind.

What rectifier are you going to use, GZ34 or the Weber replacement? After that, are you going to use the twist lok capacitor along with the cap board or will you leave it there for show? Do you have a schematic of the power supply that you can share and did you plan on any mods to it? I was talking to one of the guys on the Citation forum that suggested bypassing one of the twistlok sections with an oil filled cap to make the power supply "quicker sounding".

What does your new driver board look like and do you have a schematic? My board has individual pots to bias each tube so I was wondering why you have a single bias pot mounted between the output tubes on your chassis.

I have some pictures of my build on the photo site if you care to check them out. I ran into a few issues along the way, mostly due to limited space, and I tried to photograph my solutions. For example, I wanted to use an IEC power connector on my amp without cutting the chassis, my solution was to fashion and install a "tail" scavenged from and IEC extension cord. I locked it down inside by twisting a high tensile wire around the waist of a rubber grommet and clipping it flush with the grommet inside of the amp. Worked better for me than the standard knot. I was also able to install a "safety ground" to the chassis close to the power cord's entry point.

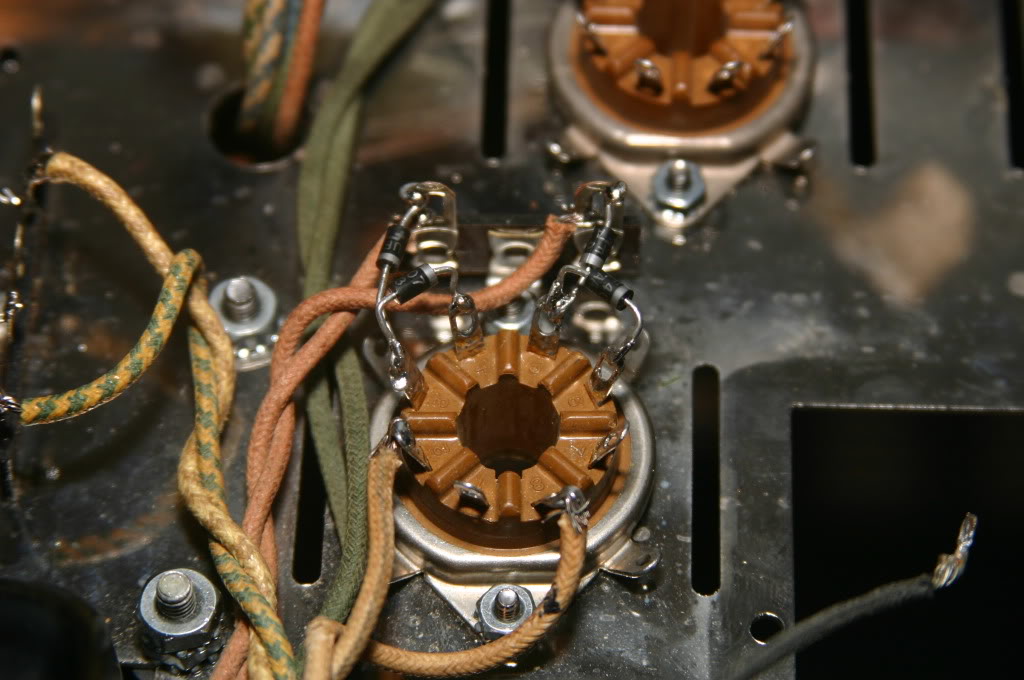

One last thing. Is that a rectifier stack I see in front of the cap board?

Again, nice work. Keep the photo's coming. Rich

Mk III Rebuild

Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

[img][/img]

[img][/img]

Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild

Re: Mk III Rebuild